Electric Copper Wire Stripping Machine 1.5 Kw Scrap Wire Stripper 69 Kg

Product Details:

| Place of Origin: | China |

| Brand Name: | TMS |

| Certification: | CO, ISO |

| Model Number: | SD-002 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | Standard exported ply wooden case or Full container for large quantity |

| Delivery Time: | 7 work days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Name: | Copper Wire Stripper | Function: | Strip Copper Cable |

|---|---|---|---|

| Wire Diameter Stripped: | 2-42 Mm | Size: | 540*410*500 Mm |

| Blades: | 4 Pieces | Wire Hole: | 7 |

| Weight: | 69 Kg | Power: | 1.5 Kw |

| Highlight: | electric cable stripping machine,scrap copper cable stripper |

||

Product Description

Electric Copper Wire Stripping Machine 1.5 Kw Scrap Wire Stripper 69 Kg

Description of copper wire stripper

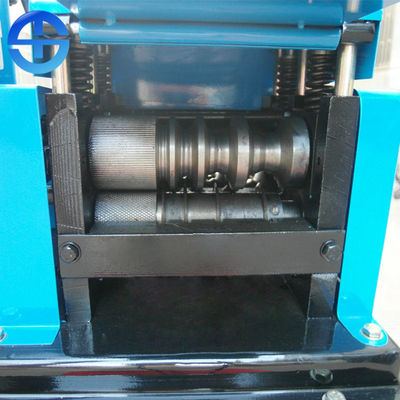

Wire stripper machine is specially used for stripping wires and cables with diameter 2-42 mm. It has novel structure, simple operation, convenient use and beautiful appearance. With upper and lower blade structure, the wires and cables can be opened up and down after stripping. It is more convenient to separate the copper core from the outer skin.

Technical specification of copper wire stripper

| Model | SD-002 |

| Power | 1.5 kw |

| Wire diameter stripped | 2-42 mm |

| Blades | 7 pcs |

| Hole | 4 |

| Size | 540*410*500 mm |

| Weight | 69 kg |

Operating instructions of copper wire stripper

1. Start the motor, check whether the operation is normal, check the diameter of rubber and plastic cable in each gear when feeding, feed one by one.

2. In order to make the blade durable for a long time, the connector of rubber and plastic cable should be cut off when feeding to avoid blade chipping.

3. If the feed is too deep and broken after coming out, pay attention to the following conditions:

(1). Adjust the tightness of the pressure of the M12 screws on both sides of the blade shaft.

(2). Check whether the position is wrong during feeding.

(3). Whether the blade is new or not, and whether the edge is too sharp, the special oilstone should be used to slightly trim until it is moderate.

4. If after feeding, the rubber and plastic have been stripped, but the copper wire can not be spit out.

There are mainly four situations

①. If the knurling of the upper shaft is too deep, the special oilstone should be used to grind the upper shaft, but not too much. Too much grinding is easy to cause the transmission of oily cable;

②. If the spring pressure is too loose, the pressure should be adjusted tightly to stop when it can be vomited;

③. If the wire diameter is too small or the gap between the upper and lower shafts is too large, the gap between the two shafts should be adjusted to 0.4-0.6mm;

④. The processed rubber and plastic cable has been heated, so the copper wire can not be spit out.

5. If the cable cannot be driven by the pressure gear after feeding and the material stays in the middle, the following situations will occur:

① Check whether the belt of each gear is loose.

② Check whether the spring pressure on both sides of each gear is too tight and there is no jacking force, so the pressure should be relaxed.

③ There is too much oil in the cable, which makes the two shafts slip, so the two shafts should be dried frequently (when drying, if the machine is running, please pay attention to safety).

![]()